Jagorar Jagorar MGP-Z Rod China Air Silinda Tube

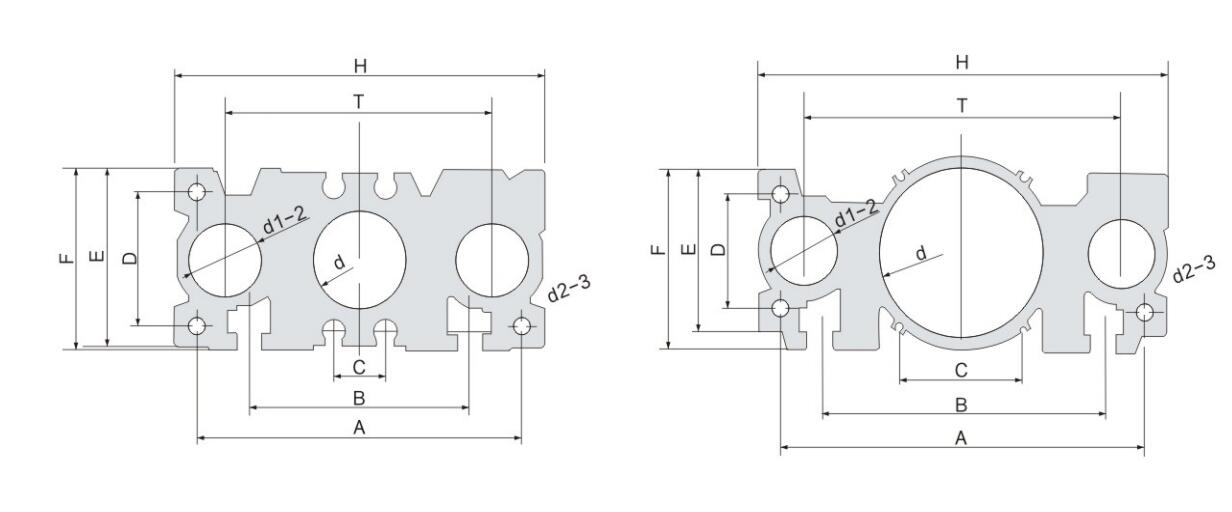

Zane-zane na MGP-Z

| NO | d | d1-2 | d2-3 | A | B | C | D | E | F | H |

| 1 | Φ12 | 9 | 3.3 | - | 37 | 8 | - | 25 | 26 | 58 |

| 2 | Φ16 | 11 | 3.5 | 56 | 38 | 8.9 | 22 | 29 | 30 | 64 |

| 3 | Φ20 | 13 | 3.5 | 72 | 44 | 8.9 | 24 | 35 | 36 | 83 |

| 4 | Φ25 | 17.5 | 4 | 82 | 50 | 11 | 30 | 41 | 42 | 93 |

| 5 | Φ32 | 21.5 | 5.8 | 98 | 63 | 23.8 | 34 | 47 | 48 | 112 |

| 6 | Φ4O | 21.5 | 6.8 | 106 | 72 | 25.4 | 40 | 53 | 54 | 120 |

| 7 | Φ50 | 26.5 | 8.5 | 130 | 92 | 25.4 | 46 | 63 | 64 | 148 |

| 8 | Φ63 | 26.5 | 8.5 | 142 | 110 | 25.4 | 58 | 77 | 78 | 162 |

| 9 | Φ80 | 33 | 8 | 180 | 140 | 61 | 54 | 76 | 92 | 202 |

| 10 | Φ100 | 39 | 11 | 210 | 166 | 73 | 62 | 101 | 112 | 240 |

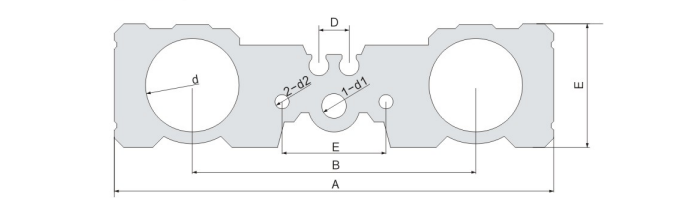

JMGPM (φ12-40) Jerin Jagoran Tubu Silinda

| No | ID | d1 | A | B | C | E | d1 | d2 |

| 1 | φ12 | φ10 | 58 | 39 | 16 | 17.2 | φ5 | φ2.4 |

| 2 | φ16 | φ12 | 64 | 42 | 16 | 18.2 | φ5.2 | φ2.4 |

| 3 | φ20 | φ16 | 83 | 54 | 19 | 22.2 | φ5.2 | φ3 |

| 4 | φ25 | φ20 | 93 | 60 | 22 | 26.2 | φ5.2 | φ3 |

| 5 | φ32 | φ25 | 109 | 70 | 23 | 32.2 | φ5.2 | φ3 |

| 6 | φ40 | φ32 | 120 | 71 | 16.5 | 41.2 | φ5.2 | φ3 |

Material na Aluminum Alloy Profile Aluminum pneumatic Silinda bututu: aluminum gami 6063 T5

Madaidaicin Tsayin mu shine 2000mm, idan kuna buƙatar sauran tsayi, da fatan za a sanar da mu da yardar kaina.

Anodized surface: Ciki tube-15± 5μm Outer tube-10± 5μm

Yarjejeniyar ƙira FESTO, SMC, Airtac, Chelic da sauransu.

Daidaita daidaitaccen ISO 6430 ISO6431 VDMA 24562 ISO15552 da sauransu.

Ana amfani dashi don daidaitaccen Silinda, ƙaramin Silinda, ƙaramin Silinda, Dual Rod Silinda, Silinda Slide Silinda, Silinda na Slide, Gripper da dai sauransu Har ila yau, don wasu na'urori na musamman.

Haɗin Kemikal:

| Haɗin Sinadari | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Bayani:

| Ƙarfin Tashin Hankali (N/mm2) | Ƙarfin Haɓaka (N/mm2) | Ƙarfafa (%) | Taurin Sama | Daidaiton Diamita na Ciki | Tashin Ciki | Madaidaici | Kuskuren Kauri |

| shafi 157 | Farashin 0.2108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Tolerancen Aluminum Alloy Tube:

| WUTAR ALUMIUM ALLOY TUBE | ||||||

| Girman Bore | HAKURI | |||||

| mm | H9(mm) | H10 (mm) | H11 (mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: Menene samfurin MGPM?

A: ☆ Ma'aunin SMC ne.Girman guntun daga Dia12mm zuwa Dia100mm.

☆Saboda sabuntawar fasaha, wannan ramin maganadisu ya canza daga murabba'i zuwa zagaye.

☆ MGPM jerin bakin ciki jagora sanda Silinda suna m a cikin tsari, kananan, kuma kada ku dauki sarari don shigarwa.Ana iya shigar da su a cikin ƙananan ƙananan wurare;za a iya gyara su kuma shigar da su daga kasa ko gefen silinda tare da sukurori, wanda ya dace don shigarwa;sandar jagorar tana da kauri kuma mai juriya Ƙarfin ɗaukar nauyi na gefe mai ƙarfi, yana iya ɗaukar nauyi mafi girma na gefe, kuma ana iya amfani dashi don turawa da ɗaga kayan aiki akan layin na'ura;tsarin sandar jagora yana da ƙarfin juriya mai ƙarfi.

☆ sandar jagorar MGP Pneumatic Silinda Silinda ce ta Pneumatic Cylinder wacce ke haɗa sandar piston da sandunan jagora guda biyu daidai da sandar piston ta ƙarshen farantin.Sabili da haka, mafi mahimmancin fasalin MGP jerin jagorar sanda Pneumatic Silinda shine babban daidaito mara jujjuyawa, wanda yake a ± 0.04 ° ~ 0.08 °, Ya dace da injin da ke buƙatar jagora mai mahimmanci.

Q2: Idan muka sayi MGPM, yana yiwuwa tare da anodizing don Pneumatic Cylinder Tube?

A: Wannan Silinda na Pneumatic Ba a ba da shawarar ya zama oxidized ba, saboda abokin ciniki yana buƙatar yanke shi da kansa sannan ya sarrafa shi sannan ya yi maganin oxygen bayan siyan shi.

Q3: Menene tsawon idan muka yi oda Pneumatic Aluminum Tube?

A: Tsawon shine mita 2.

Q4: Whulashine lokacin bayarwaofGangan Silinda na Pneumatic?

A: ☆Idan musamman tubes, lokaci bukatar 50-60 aiki kwanaki, amma idan ga misali shambura, mu isar lokaci ne 15-20 aiki kwanaki.