S45C Hard Chrome Plated Piston Rod Don Masu Silinda Mai Ruwa

Ita kuma sandar silinda mai ɗigon ruwa ta pneumatic kuma ana kiranta sanda mai chrome-plated.Sanda ce mai saman da ake bi da ita ta hanyar niƙa na musamman da plating mai wuyar chrome.Ana amfani da shi sosai a cikin nau'ikan silinda daban-daban, na'ura mai aiki da karfin ruwa, marufi, aikin katako, juzu'i, bugu da injin rini, sassan simintin gyare-gyare da sauran na'urorin watsawa ta atomatik saboda taurin sa, wanda zai iya tsawaita rayuwar sabis na injunan daidaitattun injuna da kayan aiki.

Mun ɗauki madaidaicin zanen sanyi, honing da gogewa don kera sandar piston na huhu na silinda, kowane maƙasudin fasaha ya dace da daidaitattun ƙasa.

Ƙayyadaddun Bayani

Kayan aiki: CK45(GB/T699-1999)

Ƙayyadaddun injina:

Ƙarfin ɗamara (Mpa): ≥600N/mm2

0,2 Yawan Haɓakawa(Mpa):≥355N/mm2

Tsawaitawa: min.16%

Kauri Chrome Plated: φ<20mm≥15μm, daga φ20mm ~ 20μm

Shafin: R.0.2

Hardness Chrome Layer: 850HV-1050HV

Hakuri diamita: f7,f8

Madaidaici: <0.1um/1000mm

Ovality: 1/2 haƙurin diamita

Gwajin Corroseston kimantawa: ISO 10289: 1999, IDT

Diamita na waje: 3-120mm (GCr15) 3-40m (SUS440C)

Yanayin bayarwa: Na al'ada, Harden Induction, Q+T

Teburin abun ciki na sinadaran

| HADIN KIMIYYA(%) | |||||||

| Kayan abu | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <= 0.22 | <= 1.6 | <= 0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Diamita | Nauyi | Hakuri | Hakuri | Hakuri |

| mm | Kg/m | f7 (μm) | f8 (m) | h6 (m) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9.87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Menene ma'aunin haƙuri na f7 da f8:

Matsakaicin haƙuri na f8 ya fi na f7 girma, kuma shigarwa ya dogara da matakin yankin jurewar ramuka.Misali, lokacin da ainihin girman shine 10-18, f8 (-0.016,-0.034), f7 (-0.016, -0.027), ɓacin rai na haƙuri biyu iri ɗaya ne, kewayon f7 ya fi ƙanƙanta, da yarda. kewayon shigar shigarwa ya fi karami.

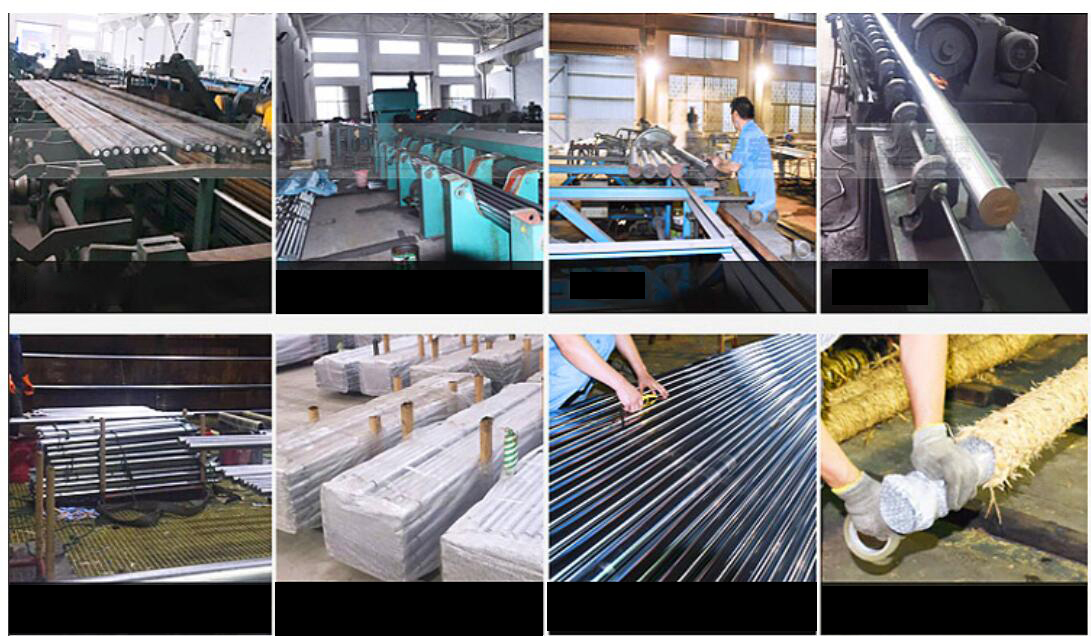

Gudun samarwa

Mataki 1: Barewa/Kwanan Sanyi:

Zane mai sanyi fasaha ce ta sarrafawa ta sandar piston silinda pneumatic.Don silinda mai ƙarfi na silinda mai ƙarfi na chrome, zane mai sanyi yana nufin zane a ƙarƙashin yanayin yanayin zafi na yau da kullun don cimma wani takamaiman tsari da wasu kaddarorin inji.Idan aka kwatanta da zafi forming, sanyi zana kayayyakin da abũbuwan amfãni daga mafi girma girma daidaito da kuma mafi ingancin saman.

Mataki na 2: Miƙewa

Wannan matakin za mu iya tabbatar da cewa sandar chrome plated mai wuya ta isa madaidaiciya.Yana da matukar mahimmanci, lokacin shigar da shi cikin silinda pneumatic.Madaidaicin madaidaiciya shine 0.2mm/m.

Mataki na 3: Girmamawa

Yin aiki na Honing shine ingantacciyar hanyar sarrafawa wanda ke ba da damar sandar sandar pneumatic Silinda don cimma daidaitattun daidaito, inganci mai inganci da tsawon rai.Yana iya inganta daidaitaccen daidaiton girman, siffar siffa da rage ƙimar Ra, amma ba zai iya inganta matsayin rami da sauran saman ba.

Mataki na 4: Gyaran sandar Karfe

Polishing yana nufin yin amfani da na'ura, sinadarai ko electrochemical sakamako don rage ƙunci na pneumatic Silinda sandar piston don samun fili mai haske da santsi.Yana da amfani da kayan aikin gogewa da barbashi masu ɓarna ko wasu kafofin watsa labarai na gogewa don gyara saman sandar fistan silinda pneumatic

Mataki 5: Chrome Plating

Chrome plating yana nufin aikin plating chromium azaman shafi akan sandar chrome mai wuyar huhu.

Layin chromium-plated yana da tauri mai girma, kuma taurinsa na iya bambanta a cikin kewayon 400-1200HV bisa ga abun da ke tattare da maganin plating da yanayin tsari.Layin chrome-plated yana da kyakkyawan juriya na zafi.Lokacin da zafi ƙasa da 500 ℃, babu wani canji na zahiri a cikin sheki da taurin.Zazzabi zai fara yin oxidize da canza launi lokacin da zafin jiki ya wuce 500 ℃, kuma taurin zai ragu lokacin da yake sama da 700 ℃.Matsakaicin juzu'i na chrome Layer ƙarami ne, musamman busassun juzu'i, wanda shine mafi ƙanƙanta a cikin duk ƙarfe.Saboda haka, chrome-plated Layer yana da kyau juriya.

Layer plating na chromium yana da kyakkyawan kwanciyar hankali na sinadarai.Ba shi da wani tasiri a cikin alkali, sulfide, nitric acid da mafi yawan kwayoyin acid, amma ana iya narkar da shi a cikin pneumatic acid (kamar pneumatic acid) da kuma sulfuric acid mai zafi.A cikin kewayon haske da ake iya gani, ƙwaƙƙwaran chromium shine kusan 65%, wanda ke tsakanin azurfa (88%) da nickel (55%).Saboda chromium ba ya canza launi, zai iya kula da bayyanarsa na dogon lokaci kuma ya fi azurfa da nickel kyau.

Mataki 6: Chrome plated sandar goge bayan plating

Electroplating da polishing: hanyoyi ne daban-daban guda biyu don kula da karafa da sauran kayan.Na farko shine maganin sinadarai, na biyun kuma magani ne na inji.

Electroplating: Hanyar yin amfani da electrolysis don haɗa Layer na fim ɗin karfe zuwa saman karfe ko wani abu.Yana iya hana lalata, haɓaka juriya, haɓakar wutar lantarki, haskakawa da haɓaka ƙayatarwa.

Polishing: Yi amfani da sassauƙan kayan aikin goge goge da barbashi masu ɓarna ko wasu kafofin watsa labarai na goge goge don gyara fuskar aikin.Polishing ba zai iya inganta daidaiton girma ko daidaiton geometric na kayan aikin ba, amma yana da nufin samun fili mai santsi ko kyalkyalin madubi.

Mataki na 7: Gwajin ingancin sandar da aka yi wa Chrome plated

Sandunan fistan da aka yi aikin lantarki da goge goge galibi suna tare da lahani kamar ramukan chrome da pitting.Girma da adadin waɗannan lahani kai tsaye suna shafar aikin sandar piston.Don rage tasirin waɗannan lahani a kan sandar piston, a gefe guda, ta hanyar inganta ingancin kayan aiki, inganta fasahar sarrafa kayan aiki, da rage faruwar lahani;a gefe guda, ya zama dole don gano lahani daidai bayan aikin gogewa don guje wa samfuran da ba su cancanta ba daga barin masana'anta.Injiniyoyin Autoair sun gane gano lahani ta atomatik tare da taimakon ilimin kimiyyar hoto

8 Mataki: Shirya

FAQ:

Q1: Mene ne pneumatic Silinda piston sanda?

A: sandar fistan wani muhimmin abu ne mai mahimmanci na kowane nau'in na'ura mai aiki da karfin ruwa ko silinda mai huhu.Sandan fistan yawanci tsayin ƙarfe ne mai ƙyalƙyali mai sanyi wanda ke watsa ƙarfin da piston ya ƙirƙira zuwa ɓangaren injin da ke yin aikin.

Q2: Menene ka'idar pneumatic Silinda piston sanda?

A: The pneumatic Silinda piston a cikin Silinda bear da tura ko ja da karfi da aka samar ta hanyar iska matsa lamba, kuma kai tsaye aiki a kan pneumatic Silinda piston sanda alaka da piston, sa'an nan kuma pneumatic Silinda piston sanda an haɗa zuwa load workpiece don motsawa. baya da baya.

Q3: Mene ne albarkatun kasa na pneumatic Silinda piston sanda

A: Yawanci, da pneumatic Silinda piston sanda na pneumatic Silinda zai zabi 45 # karfe a matsayin albarkatun kasa.Idan ana buƙatar amfani da silinda da aka samar a cikin yanayi na musamman, ana kuma iya amfani da bakin karfe 304

Q4: Me ya sa zabi 45 # karfe a matsayin albarkatun kasa

A:45# karfe ne high quality carbon tsarin karfe tare da low tauri da kuma sauki yanka.Bayan quenching, ta surface taurin iya isa 45-52HRC.Kuma yana iya samun mafi kyawun aikin yankewa da ƙarfi mafi girma, ƙarfi da sauran ƙayyadaddun kayan aikin injiniya, don haka yana ɗaya daga cikin abubuwan da aka saba amfani da su don sassan shaft.

Q5: Menene machining tsari na pneumatic Silinda piston sanda?

A: Don samun ingantacciyar ingantacciyar mashin ɗin, ba a ba da izinin daidaita sandar piston da hannu ba bayan an fara aikin.Don haka, ya kamata a aiwatar da tsarin daidaitawa kafin mashin ɗin.Saboda rashin ƙarfi na kayan aiki, jujjuya mai ƙarfi da juzu'i mai kyau dole ne a aiwatar da shi yayin aikin injin don haɓaka daidaiton mashin ɗin.Yanayin aiki na sandar fistan yana maimaituwa motsin layi.Don inganta rayuwar sabis na sandar piston, saman ya kamata ya zama chrome-plated don inganta taurin samansa da juriya.Bayan plating na chrome, ana buƙatar magani mai gogewa don samun ƙarancin ƙasa, rage juzu'i, da haɓaka aikin rufewa.Tun da polishing tsari ba shi da wani tasiri a kan m diamita na piston sanda, da workpiece bukatar a cimma wani mafi girma surface roughness kafin Chrome plating.Sabili da haka, wajibi ne don ƙara tsarin nika mai kyau kafin tsarin chrome plating (daidaitaccen nika zai iya inganta mannewar chromium. ).Dangane da binciken da ke sama, mafi dacewa hanyoyin sarrafawa don sandar fistan sune: madaidaiciya-m juyi-lafiya juyi-lafiya niƙa-chrome plating-polishing.

Q6: Menene polishing na pneumatic Silinda piston sanda

A: A lokacin aikin juyawa, rami na tsakiya wanda ke taka rawar matsayi zai nuna wani nau'i na lalacewa.Domin tabbatar da haɗewar ka'idar ma'auni, yakamata a gyara rami na tsakiya kafin a niƙa don tabbatar da ingancin sarrafawa.Lokacin yin niƙa, yakamata a yi gwajin niƙa a cikin da'irar waje kusa da ƙarshen farko, kuma ana iya yin niƙa na sandar piston kawai lokacin da yanayin runout ya cika buƙatun sarrafawa.Bugu da ƙari don haɓaka daidaiton ƙima, kyakkyawan aikin niƙa kuma yana buƙatar samun ƙarancin ƙasa mai girma akan saman injina don inganta alaƙar ions na chromium yayin aikin lantarki.Don tabbatar da cewa kauri na chromium plating Layer na sandar fistan na ƙarshe ya zama daidai, ƙarancin saman bayan niƙa mai kyau ya kamata ya kasance kusa da ƙarancin saman bayan chromium plating da gogewa.Idan ana buƙatar ƙarancin sandar piston ya zama babba, kamar Ra <0.2 μm, ya kamata ya zama ƙasa mai kyau.Add super lafiya nika ko polishing tsari bayan nika.